Pro Sailing offers boat repairs and refit together with a professional expertise and a range of services to help customers make the most of the materials and technologies.

We supply the full spectrum of marine projects using innovative, durable, industry-leading composite products.

Our services

Pro Sailing seeks the best for it’s clients offering great results with the highest quality. Combining the passion for innovation with dedication and commitment, the Company offers a personalized service tailored to the needs of each client. Pro Sailing manage to complete projects of high responsibility that ensure excellent service. We guarantee repairs and quality maintenance with the latest tools by qualified personnel.

Composites

Resin infusion

In the field of composites, resin infusion is a process where the voids in an evacuated stack of porous material are filled with a liquid resin. When the resin solidifies, the solid resin matrix binds the assembly of materials into a unified rigid composite. The reinforcement can be any porous material compatible with the resin. Typical materials are inorganic fibres (with glass fibre being most common), organic fibres such as flax, or combinations of fibres with other materials such as closed cell foams, balsawood, and honeycomb.

Prepregs

Prepregs are composite materials in which a reinforcement fiber is pre-impregnated with a thermoplastic or thermoset resin matrix in a certain ratio. Prepregs have unique properties as they are cured under high temperatures and pressures. Prepregs are being increasingly used in high performance applications in the composites industry and also in other sectors. Some key areas where prepregs currently find use are aerospace and automotive parts and components, tooling, UV resistant parts, sporting goods, high temperature parts, honeycomb and foam panels, flame retardant laminates, carbon-carbon composites and high impact surfaces.

Composites

Resin infusion

In the field of composites, resin infusion is a process where the voids in an evacuated stack of porous material are filled with a liquid resin. When the resin solidifies, the solid resin matrix binds the assembly of materials into a unified rigid composite. The reinforcement can be any porous material compatible with the resin. Typical materials are inorganic fibres (with glass fibre being most common), organic fibres such as flax, or combinations of fibres with other materials such as closed cell foams, balsawood, and honeycomb.

Prepregs

Prepregs are composite materials in which a reinforcement fiber is pre-impregnated with a thermoplastic or thermoset resin matrix in a certain ratio. Prepregs have unique properties as they are cured under high temperatures and pressures. Prepregs are being increasingly used in high performance applications in the composites industry and also in other sectors. Some key areas where prepregs currently find use are aerospace and automotive parts and components, tooling, UV resistant parts, sporting goods, high temperature parts, honeycomb and foam panels, flame retardant laminates, carbon-carbon composites and high impact surfaces.

Rigging and sails

Over the years we have specialized in the preparation of rigging, wiring and rope making to assure a great precision and safety of our clients. We provide service for all kind of yachts with the support from the leading brands in the sector of ropes, rigs, hardware and sails.

Finishing and coatings

For the finishing we exclusively work with world class brands – including Awlgrip, Dulux, International, Sikkens and Dupont – which are trusted by customers around the globe. We collaborate only with the most sustainable paints companies to focus on the things we can truly influence.

Supply

With high qualified professional team and technical resources that respond to the quality requested by the clients, Pro Sailing has got at its disposal everything needed to effectuate works for marine paint and varnishing. We supply marine products from the best brands at competitive prices and always within appropriate time limits.

Construction and refit

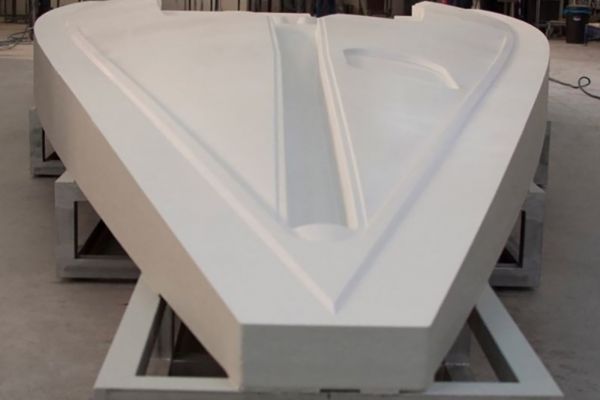

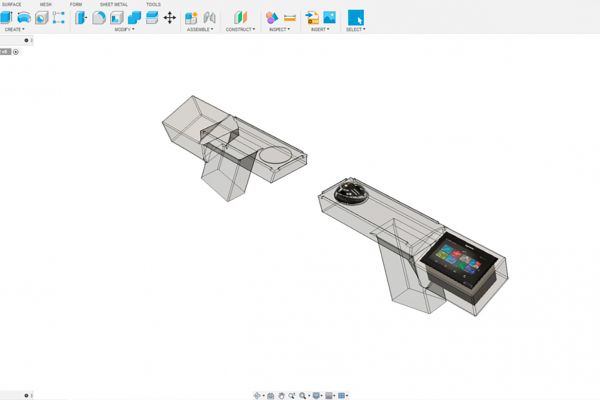

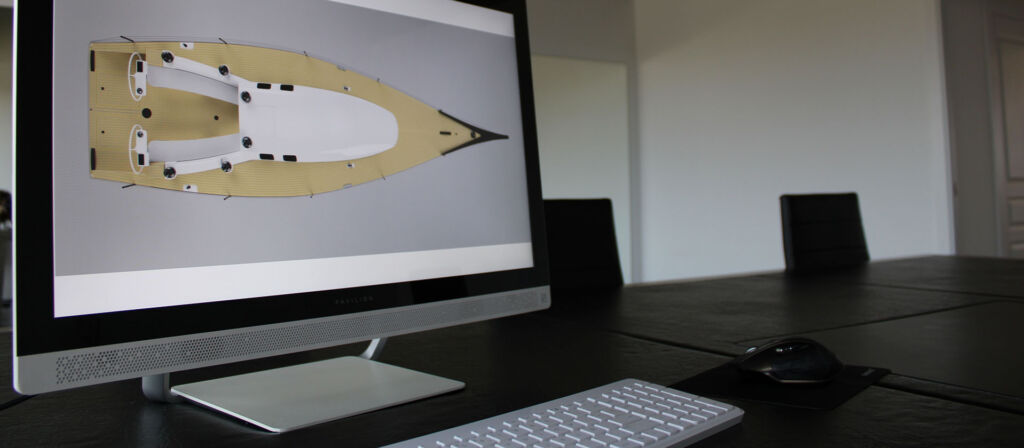

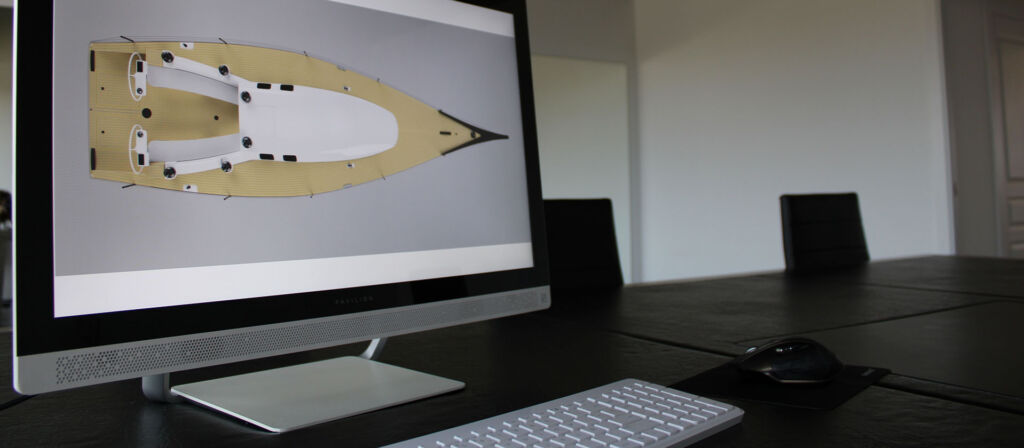

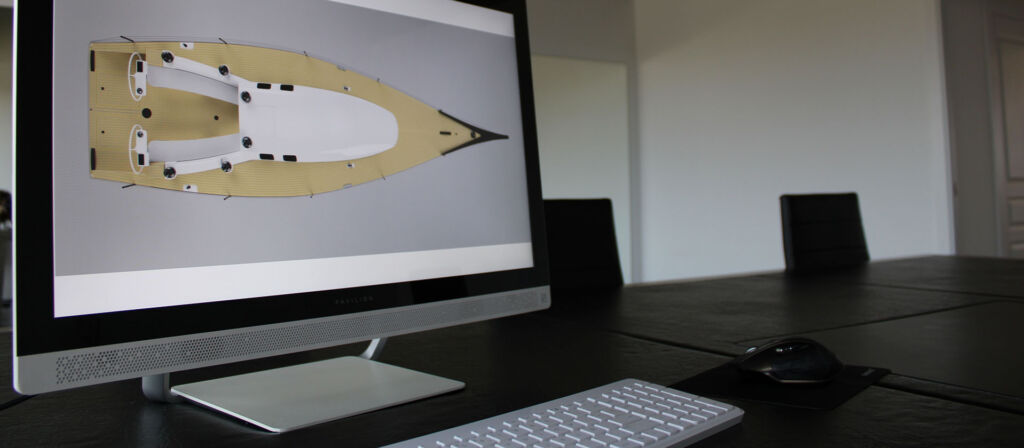

3D printing and CNC machining of moulds and prototypes

CNC provides for the possibility of high-precision milling using complex outlines as well as for 3D processing functionality. The high quality of the cutting tool, the uniformity of the cutter movement, and the wide-range adjustment of the spindle rotation speed allow for processing a wide variety of materials. Furthermore, for large-scale products, high repeatability is ensured.

Our history

Pro Sailing was established in Tarragona, Spain in 2011 responding to the increasing international demand of sail yachts refinement with cutting edge technology. Pro Sailing from the very beginning specializes in supervising and organizing the comprehensive reforms and repairs of yachts and superyachts.

Within only few years the Company expanded it’s activities to offer services for another sectors, such as aeronautics, renewable energies and construction. Now it has departments specializing in carpentry, paint, metal work and interior design. Pro Sailing has a solid team that worked together for more than 10 years, with professionalism and obsession for quality.

Our experience

The Pro Sailing’s team has performed and coordinated a large number of refit projects of various magnitudes and it is this experience, coupled with Pro Sailing’s exclusive product knowledge, that make the services on offer truly unique. Whether your needs are replacing a teak deck or interior refurbishment, you could not be in better hands than at Pro Sailing.

Our technology

To provide the best service to our clients, Pro Sailing offers a wide variety of materials and technologies such as:

Resin infusions

Prepregs

Vacuum compacted laminate

Post-curing process

Autoclave

3D printing and CNC machining of moulds and prototypes

Our facilities

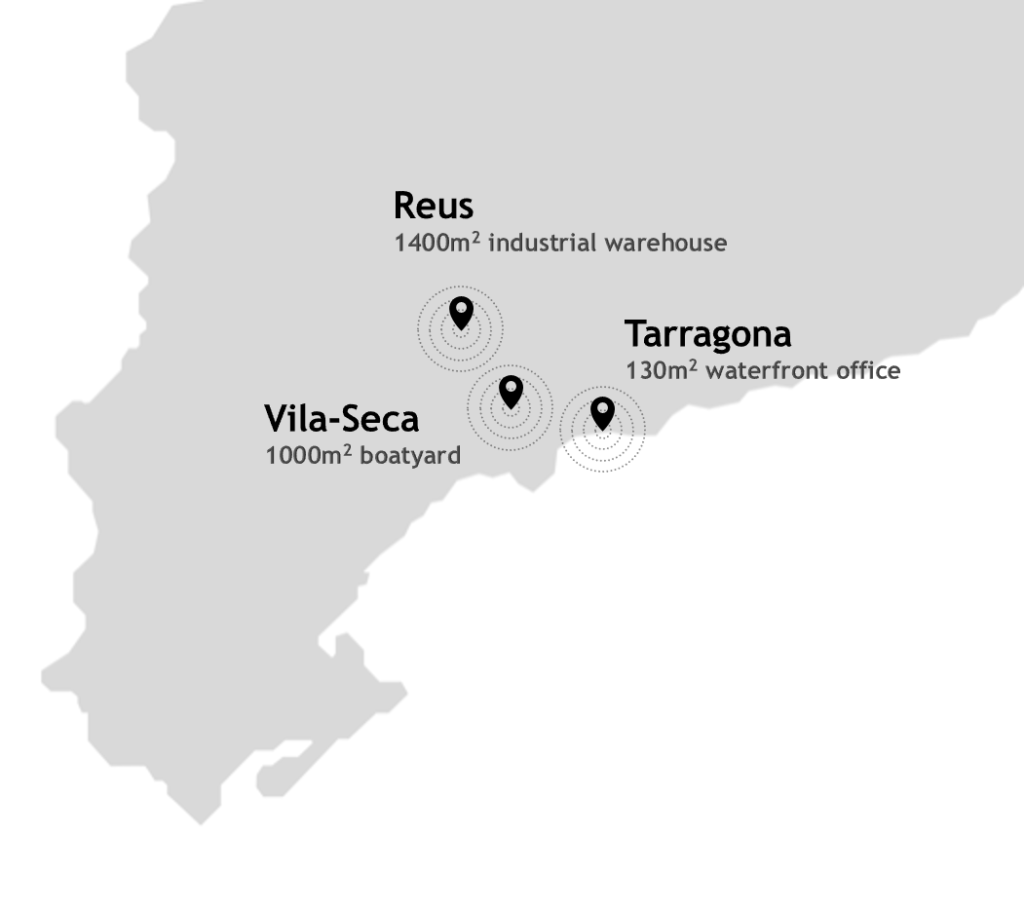

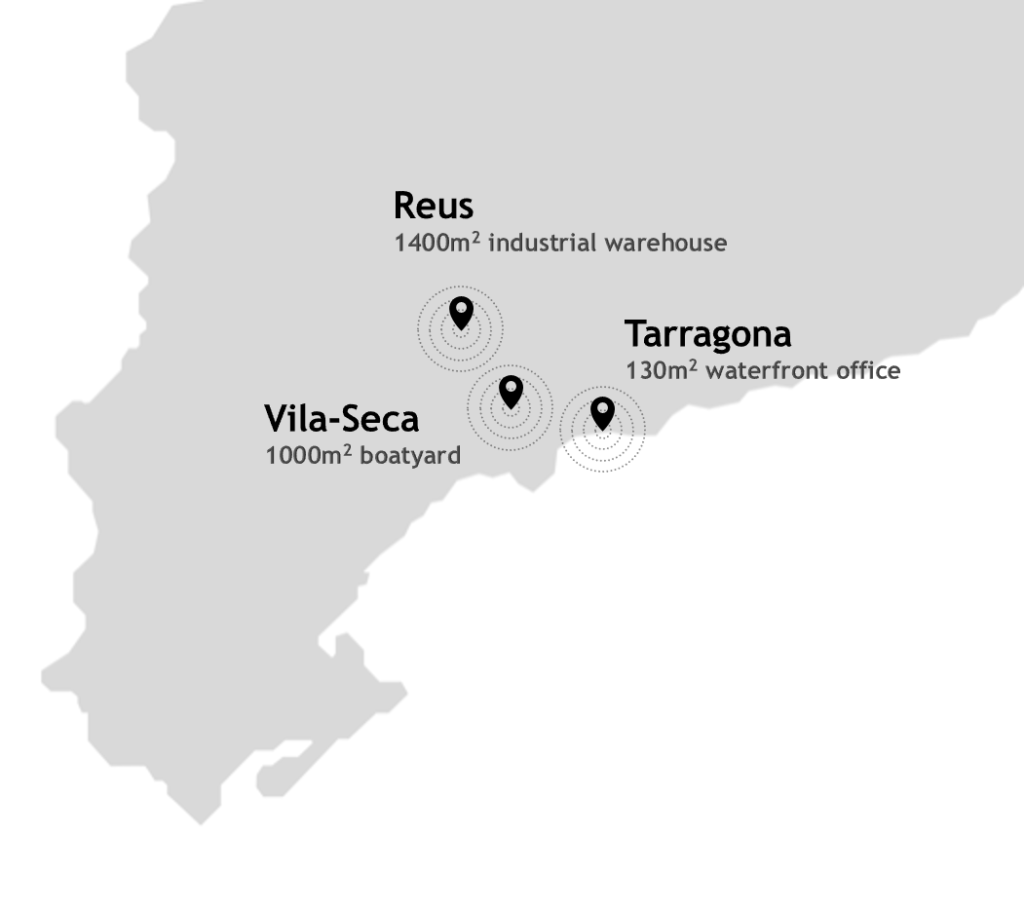

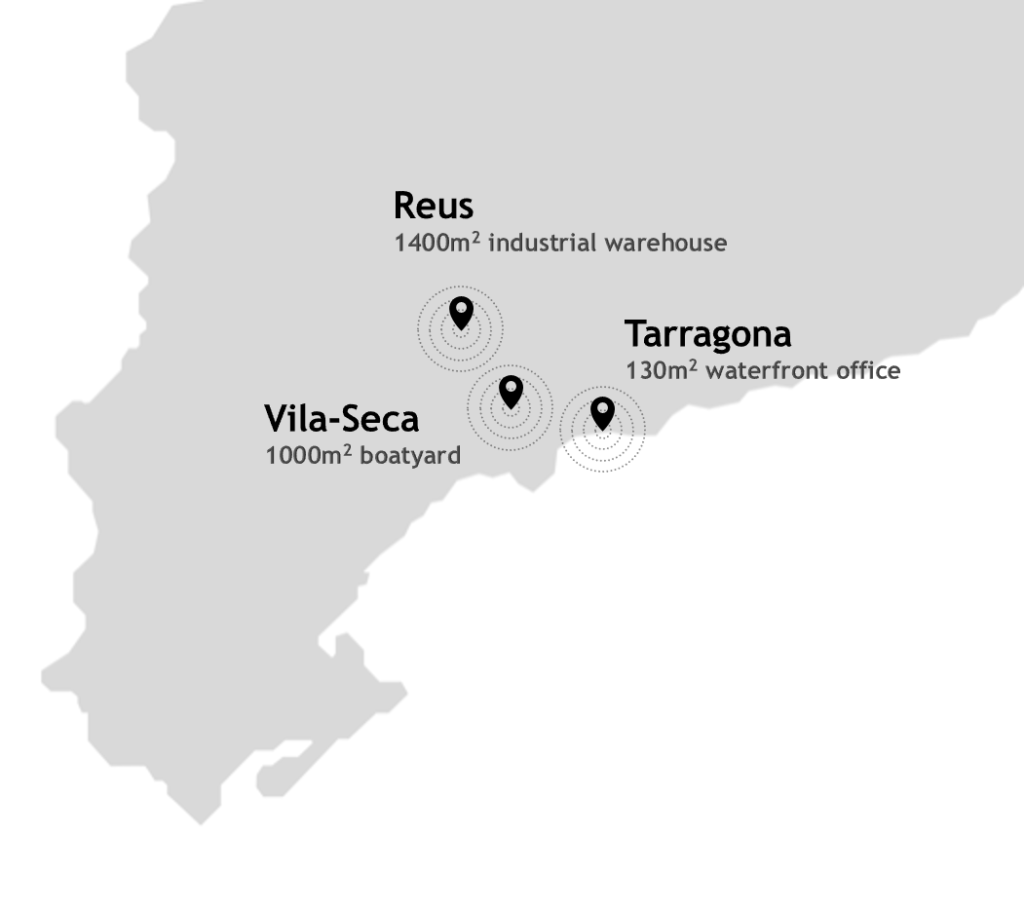

Pro Sailing’s facilities are located in the province of Tarragona, 100km to the south of Barcelona, occupying a prime location in the western Mediterranean and being well connected within Spain and to the rest of Europe.

We dispose of the total of over 2500m2 of working area divided into the boatyard, industrial warehouse and waterfront office situated in Marina Port Tarraco.

Marina Port Tarraco

Marina Port Tarraco is designed and equipped to offer a comfortable, safe and pleasant stay throughout the year. It offers 33 berths between 45 and 160 meters and a 24-hour security service. Its modern facilities provide absolute privacy, have all the services and security protocols to ensure a warm welcome and personalized assistance to all vessels and their crew. A variety of specialized companies can provide services and supplies to the yachts.

Waterfront office

Our waterfront office, situated in Marina Port Tarraco, offers personalized customer service tailored to specific needs of our clients, on-site chandlery for the basic products to perform the running maintenance job and a purchase department to find any type of spare that customers might need.

Boatyard

Pro Sailing’s boatyard offers a wide range of yacht services since we are granting to deliver high quality standards and special attention to the detailing level and finishes.

Gallery

Contact us

Waterfront office

43004 Tarragona

Tarragona, España

Boatyard

43480 Vila-seca

Tarragona, España

Customer service

Monday to Friday: 8:00 - 17:00 h